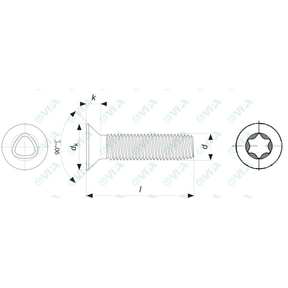

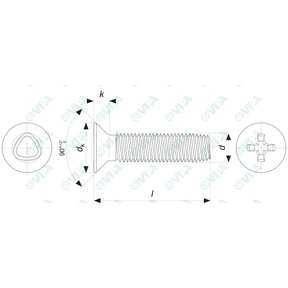

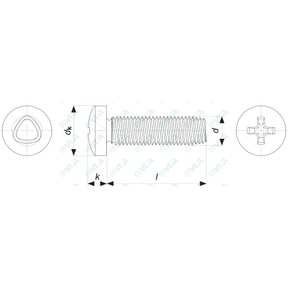

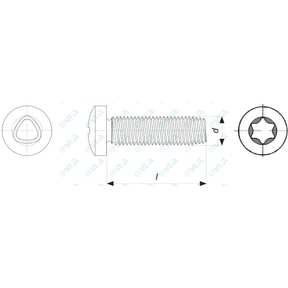

Self-forming trilobal screws are innovative fasteners designed to create their own threads during screwing, thus reducing the need for pre-drilling or pre-existing threads. Thanks to their special trilobal shape, these screws offer lower torque and greater tensile and vibration resistance, ensuring a secure and stable fastening over time.

The main fields of application for trilobular self-forming screws include the automotive industry, electronics and electromechanics, where precision and robustness of the fastening are crucial. In particular, they are used in the assembly of plastic and metal components, such as panel supports, electrical device enclosures, and engine and transmission parts. Their ability to create a self-tapping thread makes them ideal for plastics and light alloys, minimising the risk of breakage or deformation.

These screws are also particularly popular in the telecommunications and medical equipment sectors, where reliable fastening is essential. In addition, they offer significant advantages in terms of reducing assembly time, as they eliminate the need for additional operations such as prethreading, thereby optimising production efficiency.